Parson Refrigeration Leads with Newer Technologies: CO2 Projects

Parson Refrigeration has had the privilege of installing the first two major retail sites in Ottawa with transcritical CO2 refrigeration systems.

CO2 refrigeration systems have a number of advantages over standard HFC systems in that CO2 is environmentally benign, extremely efficient, can utilize much smaller refrigeration line size in comparison to standard systems, and liquid CO2 is very inexpensive in comparison to its HFC alternatives.

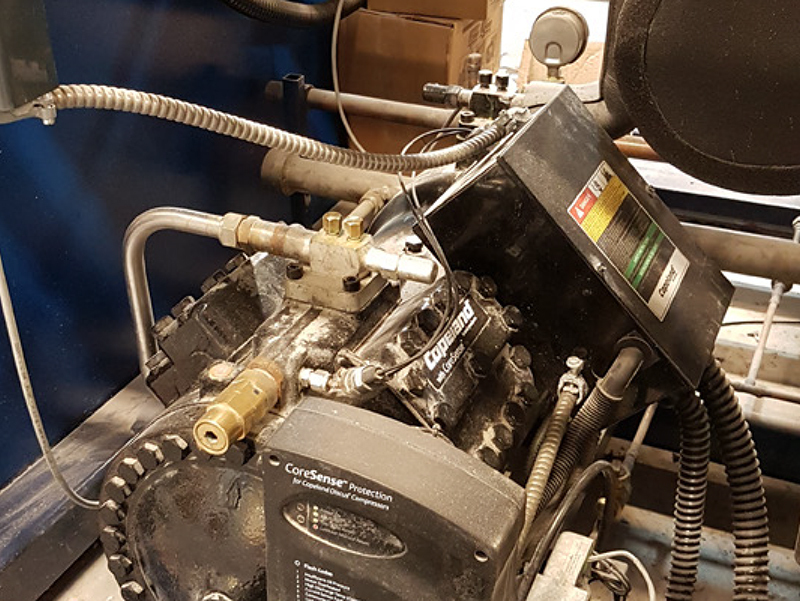

As CO2 operates at much higher pressures some of the design considerations that must be addressed are that all low side piping must be run in type K copper (thicker wall) and all high side piping must be run in stainless steel piping. All the cases and evaporator coils must also be designed for the higher pressures of CO2. Advanced control systems are mandatory for the system to operation safely and efficiently.

There are two major Canadian manufactures of CO2 compressor racks and we were fortunate to be able to work with both system at these projects.

Features

– Transcritical cycle

– Most environmentally friendly, totally benign

– Energy efficient, much lower cost than refrigerant cost

– Will never be subject to a phase-out

Challenges

– Runs at much higher pressure than conventional refrigerants

– Refrigerant charging of system requires special consideration

– Requires sophisticated control system to monitor and control operations

– More stringent regulatory requirements

Solutions

– Receive and install all equipment

– Run all low-side piping

– Manage all stainless-steel high-side piping

– Responsible for all TSSA requirements, including all submissions and coordinating inspections

– Work wit manufacturer to successfully install sophisticated control system

– Ensure system is appropriately charged to successfully introduce liquid CO2

– Extensive coordination with general contractor, all trades and store owner

Testimonials

The challenges that I faced with my first CO2 system included understanding all the different components that are installed on the rack, developing a thorough understanding of the transcritcal refrigeration system, and developing new procedures to work on the system.

It took time to get familiar with the much higher operating pressures of the system, understanding the oil management system, and all the information that is available from the electronic control system. However, once you gain hands-on experience with these new systems they start feeling very similar to convention systems.

Jim Brown

Parson Refrigeration (1985) Ltd.